Using a PLM system to manage product data and integrate and automate business processes generally results in efficiency improvements, which consequently enable companies to develop more new products, shorten time-to-market, reduce costs, increase productivity and improve the quality of products and procedures.

These efficiency improvements can generally be leveraged in two ways: Increased output with the same resources (labor, time, material) or constant output with fewer resources. The result in the first case is a higher revenue at the same costs, in the latter case it is constant revenue at lower costs. In both instances the gross margin will increase as a result of using PLM.

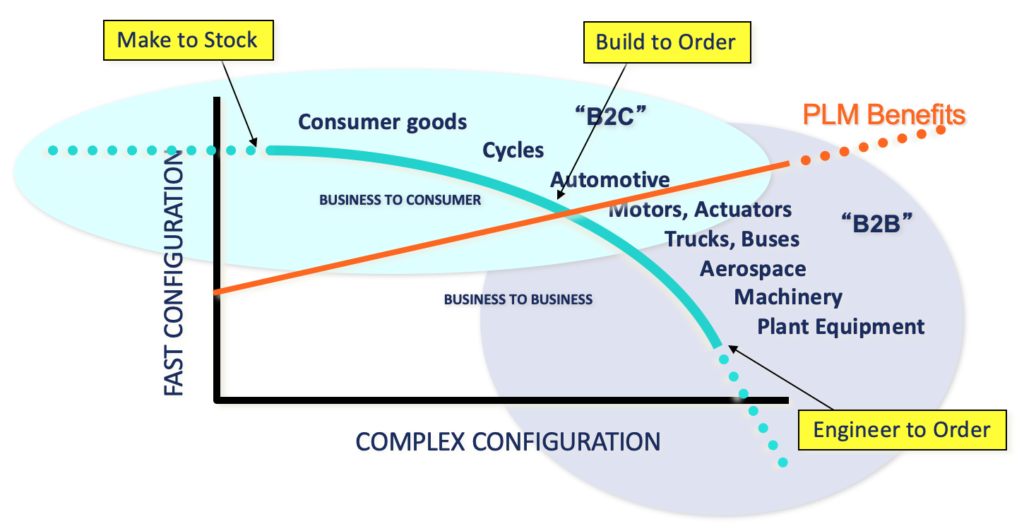

Different types of companies will achieve varying levels of benefits from PLM. On a very high level, the more complex the products are a company designs and manufactures, the higher the benefit. The illustration below shows the expected benefit as a function of the complexity of the product configuration.

In an ROI/NPV analysis the objective is to compare the increase of the gross margin with the total costs of evaluating, implementing and operating a PLM system. If the result is positive, an investment in PLM makes sense; if the result is negative, an investment usually makes no sense.

Determining detailed quantitative and qualitative (or tangible and intangible) benefits that can be expected when using PLM is difficult, although often required when building a business case for PLM and calculating the return of an investment in this technology. The biggest challenge therein is often the translation of benefits into monetary gains (which probably every CFO wants to see before signing a check).