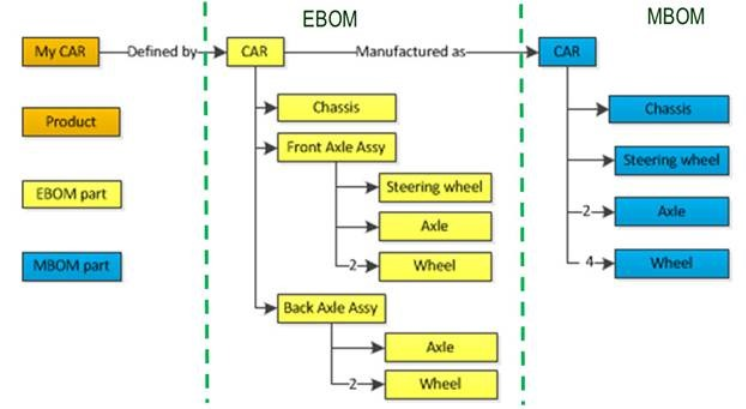

Most companies distinguish the engineering bill of material (EBOM) from the manufacturing bill of material (MBOM) or MBOMs in one way or another. The primary difference is that the EBOM is usually created by product engineering as part of the product design. It contains all engineering specified components or materials of a product and is typically functionally structured. This means, the components or materials are usually grouped in functional subassemblies, for example the chassis, the engine, the drivetrain, the interior, the wire harness, the hydraulic system, etc.

The MBOM on the other hand is usually created by manufacturing engineering as part of defining the manufacturing process. It contains all product components or materials that are on the EBOM – naturally, since all those components should obviously be used in the manufacturing process – but in addition the MBOM also contains all components and materials used only for manufacturing purposes, such as tools, fixtures, consumables, etc. that are not shipped with the product. The other big difference is that the MBOM is structured based on the sequence the product is manufactured and built and hence the order the materials have to purchased.

For example, the axle of a vehicle and the wheels may all be part of the drivetrain subassembly in the EBOM and hence be structured together. But the manufacturing sequence may be that the axle is mounted to the chassis in one of the first workstations of the assembly line whereas the wheels are not mounted to the vehicle all the way until the end, at one of the last workstations of the assembly line.

Accordingly, the axle would have to be purchased and delivered much sooner than the wheels, which could be purchased and delivered much later (assuming a just in time delivery model). Hence the axle and wheels would appear in completely different positions and structured in different manufacturing sub-assemblies in the MBOM. Consequently, the structures of the EBOM and MBOM or MBOMs are usually very different.

Lastly, another difference is that there is usually only one EBOM for a product. The structure of that EBOM is always the same and independent of where the product is manufactured. Depending on how many manufacturing sites a company has, there may be multiple different MBOMs for a product, each of those reflecting the manufacturing process at the respective manufacturing site. These manufacturing processes often vary because the machines, tools, suppliers, delivery times, and even people skills can be different between the manufacturing sites. Hence the structure of the MBOMs have to reflect the different situations and manufacturing processes in the different sites.

So do we need both an EBOM and an MBOM? The answer is a clear yes for complex products that are produced using complex manufacturing processes. For simple products without a multi-level structured EBOM that can be manufactured using a manufacturing process with only a few steps the EBOM and MBOM may be the same.