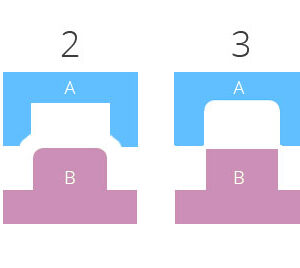

Form, Fit & Function is a change and configuration management principle that helps to determine if a component or assembly can be revised, i.e. if it can be changed by increasing the revision of the component or assembly, or if a new component or assembly has to be created and given a new part number READ MORE

Form, Fit & Function

Form, Fit & Function is a change and configuration management principle that helps to determine if a component or assembly can be revised, i.e. if it can be changed by increasing the revision of the component or assembly, or if a new component or assembly has to be created and given a new part number READ MORE

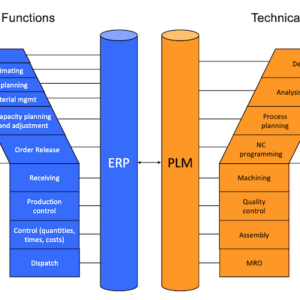

PLM Insights: What System Should Own the MBOM? PLM or ERP? Or Both?

Most discrete manufacturers would probably agree that the engineering BOM or EBOM is created and managed in PLM. And it makes sense. CAD data is typically stored and managed in PLM, and the product structure, the origin of the EBOM, is typically defined in CAD and through a CAD integration automatically transferred to PLM, where READ MORE

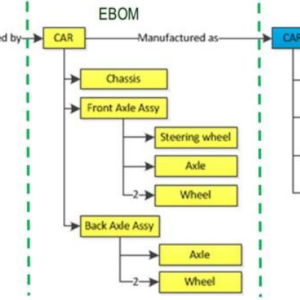

What is the difference between an EBOM and an MBOM? Do we need both?

Most companies distinguish the engineering bill of material (EBOM) from the manufacturing bill of material (MBOM) or MBOMs in one way or another. The primary difference is that the EBOM is usually created by product engineering as part of the product design. It contains all engineering specified components or materials of a product and is READ MORE

SAP – Siemens Digital Industries Partnership

Yesterday’s announcement of a partnership between two global software powerhouses to offer their customers integrated and enhanced solutions for product lifecycle management (PLM), supply chain, service and asset management can be seen as a first step towards a truly integrated product development and manufacturing environment, but also as an acknowledgement by these companies that both READ MORE