Form, Fit & Function is a change and configuration management principle that helps to determine if a component or assembly can be revised, i.e. if it can be changed by increasing the revision of the component or assembly, or if a new component or assembly has to be created and given a new part number when it is changed.

Making this determination is important when the component or assembly is used in multiple higher-level assemblies, products or at different customers, because a general rule of change and configuration management is that a component or assembly can be revised if any previous revision of this component or assembly, no matter where it is used, is fully replaceable with the latest revision. If that is not the case, i.e. if in only one instance a previous revision of a component or assembly is not replaceable with the new revision, the new component or assembly has to be given a new part number.

The implications of revising versus creating a new component or assembly are usually significant in terms of cost and effort involved. Revising a component or assembly usually involves much less effort and costs than creating a new component or assembly and assigning a new part number, in which case the downstream cost and effort to create new models, drawings and specifications, find a supplier, create new tooling and manufacturing procedures, provide additional inventory space, replace and obsolete the previous component, etc can be significant.

To help determine if a component or assembly is fully replaceable, the Form, Fit & Function principle can be used, which states that if form, fit and function of a component or assembly are maintained, it can be revised. If on the other hand form, fit or function – i.e. just one of those criteria – are not maintained, a new component or assembly has to be created and given a new part number.

Form, Fit & Function are defined as follows:

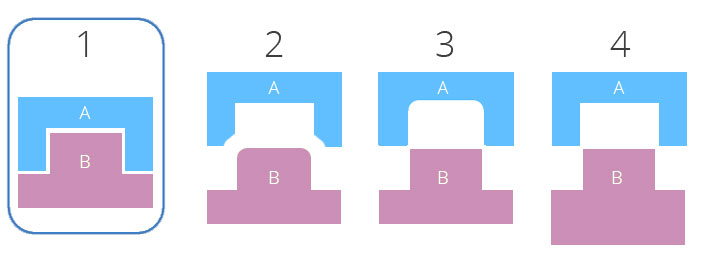

Form: This refers to the shape or geometry of a component or assembly, including its dimensions and fully extended envelope in case of an assembly. Form is maintained, i.e. the component or assembly can be revised if the shape of the component and fully-extended envelope of the assembly remain exactly the same. In all other instances a new component or assembly should be created and a new part number assigned.

If for example the shape of a component changes by modifying a 1mm chamfered edge to a 1mm rounded edge, which one could think is a relatively insignificant change, the shape is still not the same and a new part number should be assigned. The reason is that a 1mm rounded edge could potentially interfere where a 1mm chamfered edge didn’t, hence the component is not guaranteed to be replaceable in all situations.

In its extreme definition, Form also applies to the space required to assembly, disassemble, mount or remove the component or assembly in the intended location. If for example a screw is replaced with a longer screw, and the longer screw is completely inserted in a hole and hence would not change the envelope of the assembly, the assembly still may need a new part number because inserting and removing the screw in the assembled position will likely require more space and hence the fully-extended envelope of the assembly is different.

Fit: This refers to the suitability, qualification or fitness of a component or assembly. It is important to note that fit is not only limited to technical aspects and considerations, but also regulatory ones. If a component or assembly maintains its exact suitability, qualification or fitness in all instances it is used, it can be revised. In all other cases a new component or assembly should be created and a new part number assigned.

Let’s for example say a charger is currently designed to work only at 110V. Now engineering wants to change it to work both at 110V and 240V. In this instance the fit, i.e. the suitability or qualification of the charger doesn’t change, i.e. any previous chargers on the market could be replaced with the new charger. Hence the charger could just be revised as opposed to creating a new product with a new part number. There may be business reasons why a company would still want to create a new part number for the modified charger, but from a change and configuration management point of view, revising it would suffice.

In a different example, changing a material of a component may be technically possible, but it may not be legal to use the new material in all countries where the component is currently in use. Consequently not all existing components would be replaceable with a component made of the new material, and hence the existing component could not be revised but a new component would have to be created and assigned a new part number.

Function: This refers to how a component or assembly is supposed to work or perform, and what actions it is supposed to be able to do. If the original function of a component or assembly remains the same, the component or assembly can be revised. If it changes, a new component or assembly has to be created and a new part number assigned.

Function includes the overall operation of a component, assembly or product, but also its input and output as well as its internal function if it has an impact on the behavior of the component, assembly or product, or if the external environment has a different impact on the function as a result of the modification.

If for example the finish of the frame of a solar panel is modified from a polished black to a matte black – for cost reasons maybe, it does neither affect the form nor the fit of the panel, which both remain the same. It can and mostly likely will affect the function of the panel though as the matte black frame will absorb more light, the solar panel will get hotter as a result and hence the output of the panel will be reduced as solar cells lose efficiency at higher temperatures. Hence in this case changing the finish of the frame would require changing the part number of the frame and the panel because the overall output is lower, even if, aside of a slight aesthetical difference maybe, the solar panel otherwise is completely interchangeable.

Practically there is no absolute measure whether a component or assembly can be revised as opposed to having to create a new component or assembly with a new part number. Often it requires a detailed analysis or consideration of all applications where the component or assembly is used to make that determination, which typically would be done as part of a change impact analysis in an engineering change request (ECR) process.

Using the Form, Fit & Function principle as explained above and defining clear criteria what in context of a company’s products constitutes a change of form, fit and function provides a very useful framework to decide whether a component or assembly can be revised or if a new component or assembly should be created and assigned a new part number. And this in turn can lead to significant cost savings as change and configuration management mistakes as well as quality and field service problems are avoided